Definition

Businesses where process costing is used, as opposed to job costing, usually have various production stages. At each production stage, resources, such as labor, additional material, and utilities, are added. Each stage includes a large amount of costs and at each stage, resources are added to the work in process.

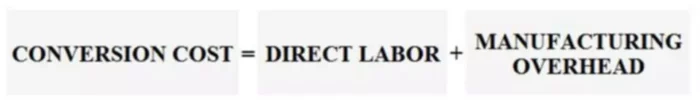

So, during the process of making our goods, we are going to take the direct labor, use some overhead and take those materials and convert them into our final goods. Accordingly, the definition of conversion costs is all costs of resources that are added at different stages, with raw materials being excluded from this equation.

Calculation

Direct labor is defined as all the costs associated with workers directly related to the making of company’s goods, such as assembly line workers. These would be salaries, insurance, and other benefits. The overhead would be anything that goes into making your product besides the materials and labor that go directly into the making of the products. Usually, a company would incur the following costs that fall under this category:

- Production facility utilities

- Depreciation of factory facility and equipment

- Indirect materials and labor.

Example calculation

Now, let’s use what we learned and the formula above to calculate conversion costs for a given example.

Life & Sports Company manufactures backpacks. The total direct materials used in production were $57,000 for the month. Total labor costs directly involved in making the backpacks were $34,600. The overhead for the same period was $78,000. Life & Sports Company made 10,000 backpacks.

The total conversion costs for this period would be direct labor ($34,600) plus overhead ($78,000) or $112,600. We can also calculate per-unit conversion costs by dividing the total conversion costs ($112,600) by the number of units manufactured (10,000). Thus, the conversion costs are $11.26 per backpack.

Knowing these numbers helps the business management make the right decisions. The business can compare this cost to the industry average or their competitors and see if they need to cut costs somewhere or increase the price for each backpack.